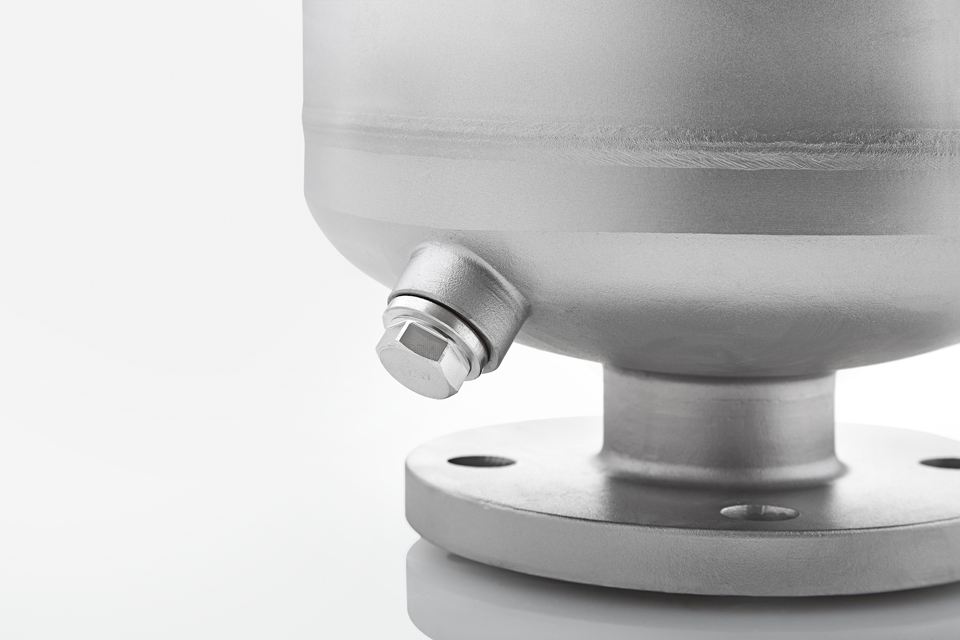

Bag filters TL

The high-quality design with lid inlet principle for optimised product flow.

The TL bag filter is a high-quality design with a lid inlet principle. This guarantees optimised product flow through the lid into the filter housing. The TL version also offers a swing eye-bold closure. Installation is carried out using the heightadjust able base frame that is supplied with the order.

| Code | ||||||

|---|---|---|---|---|---|---|

| Device type | Number of bags | Size | Material | Pressure | Connection | Connection type |

| TL | 1 | 1 | S | 10 | DN50 | F |

| Technical data | |

|---|---|

| Type | TL |

| Bag size | 1 | 2 (see ring filter bags) |

| Max. Operating data (bar): | 10 | 10 |

| Max. flow rate (m³/h): | 20 | 40 |

| Material: | Stainless steel 1.4408, 1.4571 |

| Connections: | DN50 flange (F) |